NEWS

- Company News

- Kefid's impact crusher models

- Kefid single-cylinder hydraulic

- The equipment configuration and

- The future development of minin

- K series tire mobile crusher

- Bauma China 2020: Three new pro

- Basalt sand and gravel producti

- The crushing mechanism of impac

- The use of coal gangue and crus

- 325 mesh calcium carbonate powd

- Industry News

- The maintenance measures that i

- The standard of mechanism sand

- The technological processes of

- The technical advantages of Eur

- Concrete blocks recycling to bu

- A powerful tool for processing

- Stone crusher for railway proje

- The selection of crushing cavit

- The advantages of mobile sand m

- The solution to prevent corrosi

- Exhibition

- Special Report

- Faq

- How to maintain the production

- How to configure equipment for

- The composition of cement raymo

- I want to buy a coal mill with

- What equipment is needed for th

- What are the complete sets of e

- Regarding the waste disposal af

- What is the price of sand washe

- How much are the accessories of

- What is the reason for the slow

How to choose a good solution for granite crushing production?

Asker: TorkiAsk date: 4/4/2019 03:30:26PM

Question: How to choose a good solution for granite crushing production?

Reply:

Dear Torki,

This is first determined by the properties and hardness of granite. Granite is a high-hardness rock that is difficult to crush and has a large wear on the crusher. Therefore, a reasonable crushing scheme is critical for later production.

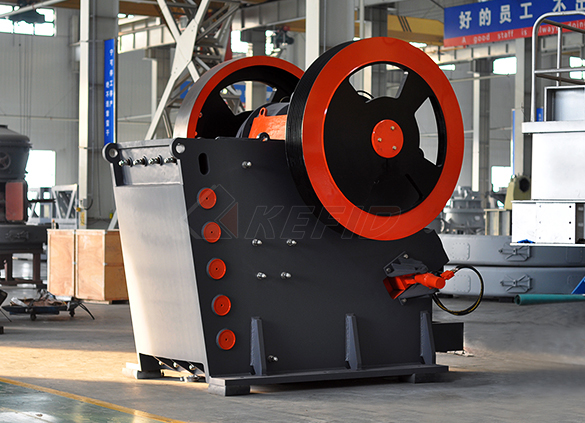

Generally, the primary crushing needs jaw crusher, the granite can be crushed to 10-30cm.

Next, for secondary crushing, hard rock such as granite, cone crusher is more suitable. Currently, there are spring cone crusher and hydraulic cone crusher. According to different cavity types, we can choose short head type and standard type, single cylinder hydraulic cone crusher and multi cylinder hydraulic cone crusher. Although the initial investment is higher, the operating cost will be much lower later, avoiding the normal operation of the production due to frequent replacement of parts and maintenance.

The cone crusher can directly crush stone into 5-10/10-15/15-20/20-31.5 and other different specifications of stone materials.

If you want to produce mechanism sand at the same time, you can add sand making machine after the cone crusher to produce 0-5mm mechanism sand.

The middle is supplemented with vibrating feeder, vibrating screen, belt conveyors, sand washing machine and other ancillary equipment.

This is a relatively complete granite crushing production line, which can increase or decrease equipment in actual production.

More details and price, please contact our 24hour online customer service.

Regards!

Kefid

Kefid