SPARE PARTS

- Stationary Crushers

- Grinding Mill

- Washing & Screening

Deep Rotor VSI Crusher

VSI-DR crusher is the main equipments for sand making machine, which can be used for metal ore, non-metal ore, construction waste, artificial sand making and reshaping. The wearing parts include upper and lower stone flowing plate, wearing plate, hammer, impact plate, distributed cone, counterattack plate, upper and lower guarding plate.

-

UPPER STONE FLOWING PLATE

Material : ZGMn13Cr2

Function : Upper flowing plate installed on the upper size of the rotor. When stones are thrown out with high speed, the upper stone flowing plate will be worn out so that the rotor is guarded.

-

LOWER STONE FLOWING PLATE

Material : ZGMn18

Function : Lower flowing plate installed on lower side of the rotor. When stones are thrown out with high speed, the lower stone flowing plate will be worn out so that the rotor is guarded.

-

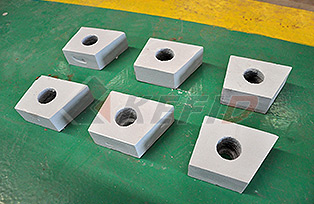

WEARING PLATE

Material : ZGMn13Cr2

Function : Wearing plate is installed on the rotor, when stone are crushed, the wearing plate will be worn and the rotor is guarded.

-

HAMMER

Material : 42CrMo

Function : Hammer is installed on the rotor. When stones are thrown out from the stone flowing plate, the hammer will be worn out so that the rotor is guarded.

-

IMPACT PLATE

Material : High iron

Function : Impact plate is installed on the rotor, the material is hit by the impact plate and bounced out of the rotor. When changing the impact plate, please keep balance.

-

DISTRIBUTING CONE

Material : High iron

Function : Distributing cone is hang under the hopper, used for changing the different feeding ways of “center feeding” and “center and ring feeding”

-

GUARD LINER PLATE

GUARD LINER PLATEMaterial : ZGMn13Cr2

Function : Counterattack plate is installed on the inner side of the frame. When the material is thrown out from the rotor, the material will be impact by the counterattack plate for crushing. The frame of the equipment will be guarded because of the counterattack plate.

-

UPPER GUARDING PLATE

Material : ZGMn13Cr2

Function : The guarding plate is installed inside the equipment to guard the worn of the main frame.

-

LOWER GUARDING PLATE

Material : ZGMn13Cr2

Function : The guarding plate is installed inside the equipment to guard the worn of the main frame.

EXCHANGE METHOD OF ROTOR AND ITS EASY-WEAR PARTS

1. clean the top part, please set up a windshield in windy season.

2. Loosen the cover fixing bolts (see Figure 11-1) Lift the hopper by manual hydraulic jack, rotate the hopper so it cannot move freely.

3. clean dust from the distribution plate, loosen the bolts and lift the distribution plate from the frame.

4. loosen the fixing bolts of rotor, remove the distribution cone, lift the rotor out of the body slowly, so as not to damage the main shaft.

5. easy wearing parts include: upper and lower stone flowing plate, wearing plate, impact plate, and hammer. Exchange method: Remove the bolt, rubber gasket and nut, exchange the wearing parts with new parts, then replace the bolts, rubber gasket and nuts. Please note that, when exchange the easy-wearing parts, keep the rotor balancing on each direction, otherwise causes vibration of machine.

6. when disassemble the rotor, please pay attention to the O sealing ring between the rotor hub and main shaft, which cannot be lost.

THE REPLACE OF THE UPPER AND LOWER GUARDING PLATE

1. Clear away the lining material in the crushing chamber.

2. Removing the bolt and change the upper and lower guarding plate.

3. Please note not damaging the main shaft. Hydraulic jack, inlet hopper, distributing plate, bolt fasten the distributing plate, rotor, surrounding guarding plate, fasten plate for the surrounding guarding plate, hang out from the upper side, upper and lower guarding plate.

REPLACE OF THE IMPACT PLATE

1. Remove the bolt.

2. Take out the impact plate, and replace the new one.

3. Fasten the bolt.